Quanzhou Jingli Engineering & Machinery Co.,Ltd.

JingGong Excavator is your best choice for wheel excavator, crawler excavator, sugarcane harvester, and sugarcane grapple loader in China.

Jinggong Excavator has 20 years experience in manufacturing mini excavator. Buy mini digger,wheel excavator,crawler excavator,grapple excavator,hi-rail excavator,and other customized excavator at factory price. Best operating system, high work efficiency.

360 degree rotation makes the machine more flexible,the maximum digging reaches 4.1 meter.

The imported KYB or DOOSAN dual-speed walking motor leads to the popularity of this compact excavator in small- and medium-scale construction sites.

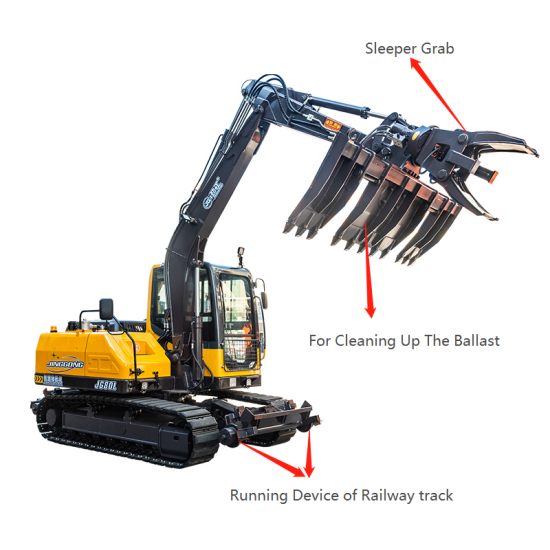

We are a factory specializing in the production of railway excavator and a supplier of railway machinery. With over 20 years of manufacturing experience and comprehensive after-sales service. We can customize Hirail machines according to customer needs. If you have any needs, please contact us promptly! This crawler excavator is specially designed for the replacement of railway sleepers. The average Each pillow changing machine can replace 1.5 pillows per minute, which greatly reduces the labor management cost and improves the operation safety.

This machine can cut sugarcane quickly with a special cutting blade. The collecting hopper at the rear of the harvest can collect the cut sugar cane in an orderly manner, which improves work efficiency.

Digging, slewing, compound operation, fuel consumption and other properties are perfectly adjusted to ensure excellent response to various working conditions.

JG 75L has beautiful appearance, high configuration, superior performance, low fuel consumption, and wide operating range. It is suitable for land loosening of vegetable greenhouses, landscaping in municipal departments, digging pits in orchard nurseries, concrete pavement breaking, sand and stone mixing, and construction operations with narrow space.

Equipped with high quality engine and steel, JG75S wheel excavator provides a compact design and outstanding properties. This wheeled excavator can be equipped with breaking hammer, grip, auger bit and other assistant devices. In order for quality control, every excavator must undergo strict examination and inspection by our skilled workers.

The grab has a 360° rotation angle, realizing a significant decrease in loading and unloading time and cost of woods, sugarcanes or other similar materials.

China Top Brand, Jinggong Excavator offer latest mini excavator details, and more information about agricultural and construction equipment industry news.

In a recent development that underscores the growing global interconnectedness within the manufacturing sector, a delegation of esteemed Russian clients arrived at our factory premises to explore potential collaboration avenues. The visit marked a significant milestone in fostering international partnerships within the industry. The Russian delegation, comprising seasoned professionals from various sectors, was warmly welcomed. The day-long itinerary was meticulously planned to showcase our advanced manufacturing capabilities, innovative technologies, and quality assurance processes. During the tour, the clients were impressed by the state-of-the-art machinery and the seamless integration of automation in our production lines. Our experts provided comprehensive insights into the entire manufacturing lifecycle, from raw material sourcing to finished product delivery. This transparent approach fostered an environment of trust and mutual understanding. The highlight of the visit was an in-depth discussion session focused on exploring synergies between our companies. Both parties exchanged ideas on potential collaboration models, including joint product development, technology transfer, and market expansion strategies. The constructive dialogue underscored the shared vision of driving innovation and enhancing competitiveness in the global market. As the visit drew to a close, both sides expressed optimism about the future prospects of collaboration. Our factory looks forward to leveraging this opportunity to strengthen its global footprint and tap into new markets. The Russian clients, similarly, were enthusiastic about the potential for mutual growth and success. This visit serves as a testament to the enduring power of face-to-face interactions in nurturing business relationships and fostering long-term collaborations within the manufacturing industry.

2024-10-09JG Engineering Machinery, a global construction equipment leader, announces its National Day holiday from Oct 1st to 3rd (Beijing Time). The company wishes all stakeholders a happy National Day. During this period, customer service will operate with limited hours. Urgent matters should be addressed via emergency contacts on the website. JG values this festive break to recharge and reinforce commitments. Follow us on social media for updates. Enjoy the celebrations!

2024-09-30In the colossal undertaking of railway construction, the railway excavator stands as the cornerstone equipment, necessitating meticulous daily maintenance for uninterrupted and optimal performance. To uphold its efficiency and reliability, the following maintenance considerations are paramount: Fuel Management: Select the appropriate fuel and routinely inspect the fuel filter to block contaminants from infiltrating the fuel system. Additionally, maintain a clean fuel tank to prevent water contamination. Filter Maintenance: Regularly replace air, fuel, and hydraulic oil filters to preserve the cleanliness and efficacy of both the engine and hydraulic systems. Cooling System Upkeep: Monitor coolant levels and quality, while performing regular cleaning to prevent scale and rust buildup, which can hinder heat dissipation. Brake & Transmission Integrity: Vigilantly assess brake force and disc wear, adjusting or replacing components promptly. Concurrently, inspect transmission parts for wear and tightness to guarantee stable mobility. Electrical System Inspection: Routinely check electrical wiring and connectors for signs of damage or aging. Furthermore, ensure the seamless functioning of sensors, gauges, and other electrical components. Lubrication & Fastening: Regularly lubricate all lubrication points and inspect fasteners for loosening, reinforcing the excavator's structural stability. Hygiene & Maintenance: Maintain a spotless exterior and interior cab, regularly eliminating dirt, oil, and debris. Moreover, adhere to operational guidelines to prevent overloading and abusive operation. Professional Maintenance: Complementing daily maintenance, periodically engage professional technicians for comprehensive inspections and maintenance, ensuring peak machine performance. The diligent execution of these daily maintenance practices is crucial for ensuring the railway excavator's efficient and reliable operation. By doing so, not only is the equipment's lifespan extended and operational efficiency enhanced, but also a robust support is provided to the railway construction industry.

2024-09-20Scan to wechat :