Tel/Whatsapp : +8613799243565

Fax : 13799243565

Jinggong JG100X Elevated Cab Loader: Redefining Efficiency and Operator-Centric Engineering The Jinggong JG100X Elevated Cab Loader represents a groundbreaking leap in heavy machinery innovation, meticulously engineered to address the evolving demands of modern construction, industrial material handling, and large-scale logistics operations. Designed with a 3.8-meter elevated operator cabin featuring 270° panoramic tempered glass windows, this machine delivers 40% wider visibility compared to traditional loaders, effectively eliminating blind spots in complex worksites such as steel mills, port terminals, and demolition zones. Core Performance Enhancements At its heart lies a YUCHAI Tier 4 Final-compliant diesel engine (118 kW/2200 RPM) paired with an intelligent hydraulic system delivering 300 L/min flow rates, enabling seamless integration with grapples, buckets, and specialized attachments for scrap metal sorting, concrete debris handling, and bulk material transfer. The 10-ton lifting capacity combined with Smart Load-Sensing Technology ensures optimal power distribution, achieving 22% faster cycle times while reducing fuel consumption by 18% during intermittent operations. Ergonomic Revolution The JG100X redefines operator comfort through its ROPS/FOPS-certified cabin equipped with air-ride suspension seats, multi-axis adjustable controls, and a NOISE ≤70 dB environment. The 7-inch LCD touchscreen provides real-time diagnostics for critical parameters including hydraulic pressure, engine temperature, and attachment compatibility, while the AI-assisted Stability Control System automatically adjusts counterweight distribution when operating on slopes up to 30° gradients. Technical Innovations - Modular Quick-Attach Interface: Enables sub-90-second tool swaps between magnetic separators, timber grabs, and demolition shears, supported by ISO 13031-compliant coupling mechanisms - Hybrid Power Option: Available electric-diesel dual-mode configuration meets stringent urban emission regulations (EPA Phase 3/EU Stage V) - Predictive Maintenance Hub: Integrated IoT sensors monitor component wear (e.g., hydraulic pumps, track motors) and generate maintenance alerts via JG Smart Fleet Platform Certified to CE, ISO 9001, and ANSI/SAIA A92.8-2024 standards, the JG100X excels in high-risk environments like railway ballast cleaning and hazardous waste facilities, featuring explosion-proof wiring and EMI-shielded electronics for uninterrupted operation near electromagnetic interference sources. Strategic Applications From precision scrap bale stacking in recycling plants to rapid disaster relief material relocation, the JG100X’s variable undercarriage configurations (standard track/rubber-tire/rail-mounted) adapt to diverse terrains. Its reinforced boom structure with 20% higher fatigue resistance ensures longevity in 24/7 mining operations, while the frost-resistant hydraulic fluid system maintains performance at -25°C for Arctic infrastructure projects. Jinggong’s JG100X isn’t merely a loader—it’s a transformative asset for industries prioritizing operator safety, environmental compliance, and total cost of ownership optimization, setting new benchmarks in the global heavy equipment sector.

Item NO.:

JG-100ZLead Time:

15-45daysProduct Origin:

ChinaBrand:

JingGongShipping Port:

xiamenPayment:

L/C or T/TPrice Range:

1-5/35000$Price Range:

6-10/30000$Color:

blue/orange/yellow

Tel/Whatsapp : +8613799243565

Fax : 13799243565

Email : sales@fjjgjx.com

Skype : +8613799243565

Heavy Duty Grapple Excavator Hydraulic Rotating Claw Material Handling Machine For Scrap Recycling

| Log Loader Grapple Features

1.Operator can control the rotating speed.

2.Unlimited clockwise and anti-clockwise 360 degree rotatable.

3.Flexible choices dependend on job environment.

| Main Parameters

|

Length*width*height |

6450*2230*3050mm |

|

Maximum Radius Weight Capacity |

0.8-0.9t |

|

Grapple Rotation Angle |

360° |

|

Rated Power |

65KW |

|

Machine weight |

8600KG |

| Main Parts of Hydraulic Excavator

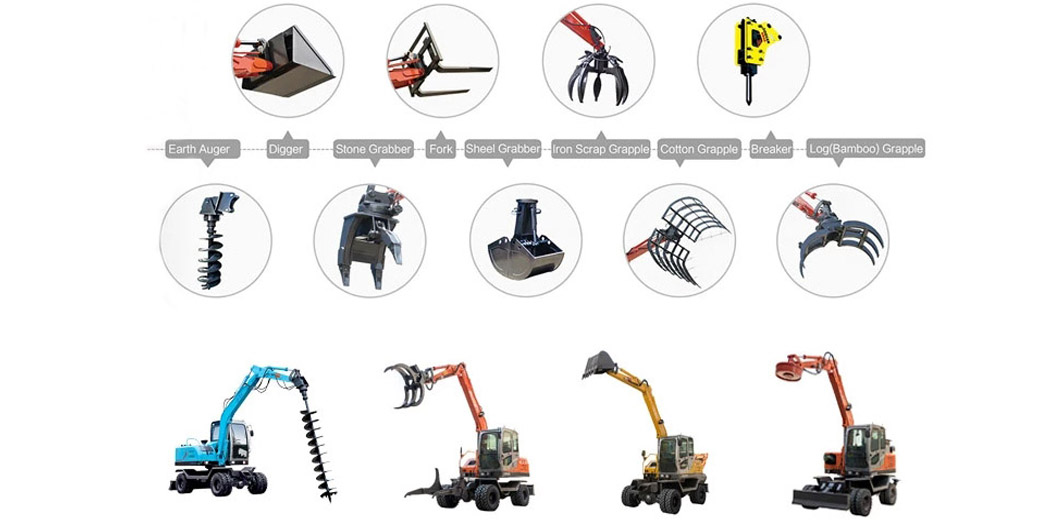

We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.

| Why Choose Us

1. Use specified high-quality cylinder

2. Development Patent: Grapple rotates flexibly to improve work efficiency

3. The whole machine use high-quality steel, which is strong, reliable and more durable

| Company

We are a leading manufacturer and exporter of wheel excavators, crawler excavators, sugarcane harvesters, sugarcane grab loaders, multi-function excavators. We have nearly 20 years of professional experience, and our products have been exported to many countries.

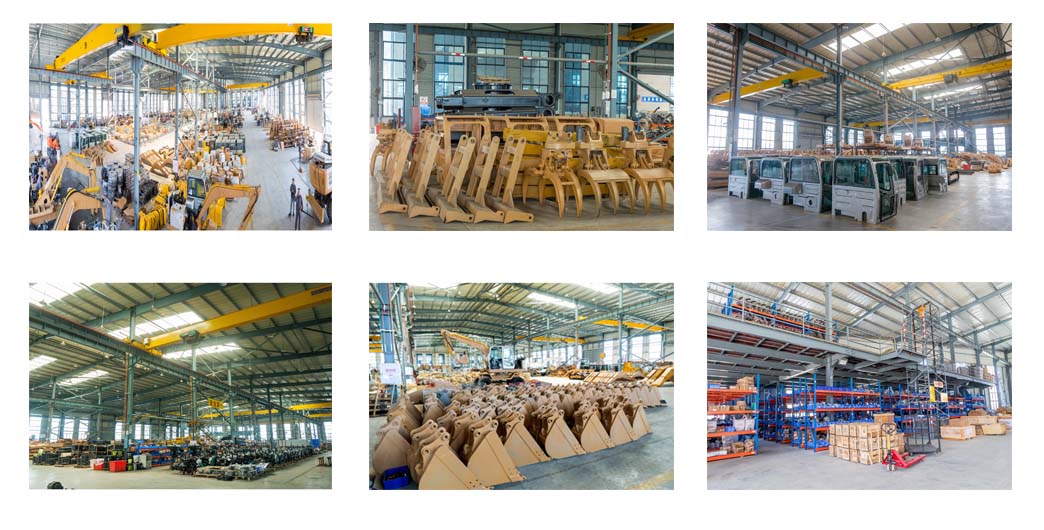

| Workshop Display

Our company abides by the business philosophy of "quality first, customer first" to ensure product quality. We have rigorous production procedures, and each production process is carried out under strict quality inspection.Only after passing the inspection can they move on to the next procedure. At the same time, we insist on creating a neat, clean and safe working environment.

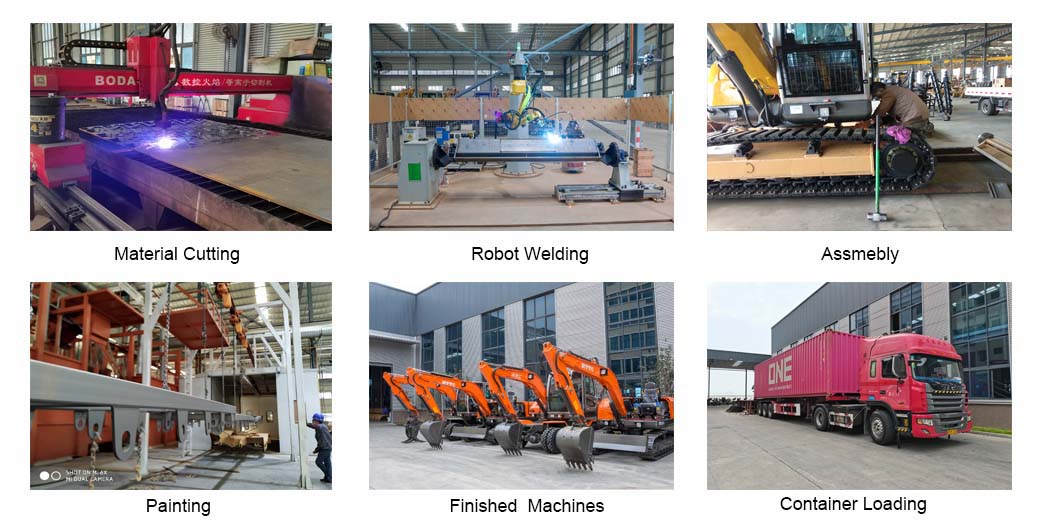

| Process

| Exhibition Show

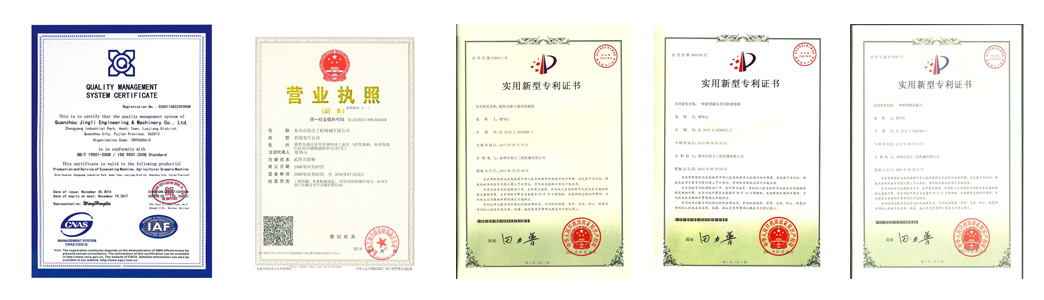

| Certificates

FAQ

Q: What logistics ways we can work for shipment?

A: We can ship construction machinery by various transportation tools.

1. For 90% of our shipment, we will go by sea. to all main continents such as South America, Middle East, Africa, Oceania and Europe etc. either by container or RoRo/Bulk shipment.

2. For neighborhood countries of China, such as Russia. Mongolia. Kazakhstan. Uzbekistan etc., we can ship construction machinery by road or railway.

3. For light spare parts in urgent demand, we can ship it by international courier service, such as DHL,TNT UPS, or Fedex.

Q: How long is the warranty?

A: We can offer 3-years warranty for the whole machine.

| SPECIFICATIONS | ||||||||||

| RANGE OF OPERATION | Boom length | 3670mm | ||||||||

| Arm length | 1860mm-2650mm | |||||||||

| Max radius of capture | 7000-7800mm | |||||||||

| Grab the biggest opening width | 1250mm | |||||||||

| Grab the minimum opening width | 80mm | |||||||||

| Maximum radius weight capacity | 800-900kg | |||||||||

| Grapple rotation angel | 360° | |||||||||

| Maximum Dumoing height | 4650-5100mm | |||||||||

| Back-End radius of gyration | 198mm | |||||||||

| Max lifting height of cab | 800mm | |||||||||

| Max extended distance of arm | 800mm | |||||||||

| DIMENSION | (Length*width*height) travel position | 6450*2230*3050mm | ||||||||

| Wheel base | 2430mm | |||||||||

| Track(Front/rear) | 1850mm/1750mm | |||||||||

| Ground clearance of counterweight | 1060mm | |||||||||

| Min ground clearance | 200mm | |||||||||

| TECHNICAL PARAMETERS | Angle of rotation | 360° | ||||||||

| Machine weight | 8600kg | |||||||||

| Rated Speed | 2400r/min | |||||||||

| Hydraulic system working pressure | 21Mpa | |||||||||

| Hydraulic system flow | 150L/min | |||||||||

| Variable piston pump | 71ml/r | |||||||||

| Max Hauling force | 58.5KN | |||||||||

| Walking speed | 25km/h | |||||||||

| Grade Climbing ability | 58%/30° | |||||||||

| Tyre model | 825.16 | |||||||||

| Volume Of Bucket | 0.35m3 | |||||||||

| Revolution Overdrive Pressure | 20Mpa | |||||||||

| Full circle swinging time | 5.5s | |||||||||

| Fqt Fuel Quantity | ≥4L/h | |||||||||

| Hydraulic Tank Capacity | 110L | |||||||||

| Capacity Of The Fuel Tank | 110L | |||||||||

Scan to wechat :